What is a Stepper Motor and How it Works?

Have you ever thought

about how a robotic arm moves with precision or

how graphic printers create accurate replications of images, or how consumable products are moved precisely around a

plant floor or any other type of motion control positioning system? With this

lesson and others to follow you will learn about motion control using different

types of motors available, primarily stepper and servo motors. Selecting

between a servo motor and a stepper motor can be quite a challenge with the

balancing of several design factors in cost considerations, torque, speed,

acceleration, and drive circuitry all play an important role in selecting the

best motor for your application.

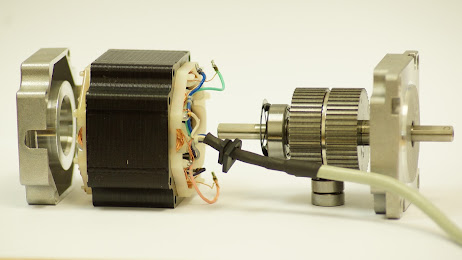

In this lesson we will

discuss what a stepper motor is and how it works, so let’s first determine what

a stepper motor is and examine some unique features of a stepper motor. Stepper

motors have a permanent magnetic rotating shaft called a rotor and stationary

electromagnets surrounding the rotor called the stator. Stepper motors have

typically 50 to 100 electromagnet poles (pairs of north and south poles) generated

either by a permanent magnet or an electric current. Each permanent magnet pole

offers a natural stopping point for the motor shaft. The greater number of

poles allows for a stepper motor to position itself accurately and precisely

between each of the poles. This is a convenient feature of the stepper motor in

that the poles within a stepper motor allow it to be positioned accurately

without any positional feedback, In other words it works in an open-loop

control system. The open-loop control allows for a single electrical pulse from

a controller to move the motor shaft from one pole to the other and stop

aligned with the electromagnetic pole without positional feedback to the

controller. This is one of the benefits of the stepper motor, but additional

benefits of a stepper motor will be discussed in a separate article.

When we want to increase

the resolution or achieve the smallest rotational movement, the design of the stepper

will contain a larger number of magnetic poles. Basically, the incremental step

size of a stepper motor is fixed to a certain degree of rotation based on the

number of electromagnet poles. Therefore, moving to an accurate position is

simply a matter of sending the correct number of pulse commands. Stepper motors

may have up to 200 rotor teeth, or 200-400 full steps per revolution of the

motor shaft. To determine the resolution of rotation we can perform a little

math. If a stepper motor has 200 incremental steps and we know a full rotation

is equal to a circle or 360-degrees then we can divide 360-degrees by 200. This

equates to 1.8-degrees of a full step angle rotation. 400 steps divided into

360-degrees provides 0.9-degrees of full step angle rotation. Outputting one

digital pulse from the controller driver is equivalent to one step of rotation.

Now let’s follow a simple movement diagram of a stepper motor

to determine how the

stepper motor works in one complete rotation. At position 1, the rotor is

started at the top electromagnet pole, which is currently energized with

current flowing through the wire. Now in order to move the stepper rotor

clockwise (CW) the top electromagnet pole is deactivated and the right

electromagnet pole is activated causing the rotor to move 90 degrees CW and

align with the active magnet as shown in position 2. Now as we continue to

deactivate and activate the electromagnet poles around the stator in positions

3 and 4 causing the rotor to re-align with each new electromagnet pole we

enable the rotor to rotate 90 degrees CW each time, this eventually completes a

full 360-degrees of rotation. Hint: Remember how like magnetic poles repel and

unlike poles attract. Depending on whether the power source current is applied

to electromagnetic pole coil wire we can cause LIKE and UNLIKE magnetic

attraction and re-attraction forcing the permanent magnet rotor to move. In the

real-world stepper motors incorporate a larger number of electromagnet poles on

the stator and rotor to increase the resolution as we have discussed earlier. With

this increase in the number electromagnet poles the operation is basically the

same as the example provided using 90-degree rotation but now the rotation

would be more like 1.8-degrees of rotation as mentioned earlier.

An example of a multi-pole stepper motor is illustrated here. In position 1 the rotor is aligned in the upper position with the top stator electromagnetic activated indicating S for South polarization and in position 2 the top electromagnet stator is de-energized and the electromagnet stator to the right is energized the rotor moves clockwise and aligns with this electromagnet indicating the new S polarization allowing for a precise rotational movement of degrees. This changing of the electromagnetic polarization continues creating 360-degree rotation. The faster the electromagnetic polarization occurs the faster the speed.

Comments

Post a Comment